Electric Control Valve

Cryogenic Pneumatic Control Valve

cryogenic pneumatic control valve

Pneumatic cryogenic regulating valve is used for liquefied natural gas,liquefied petroleum gas,liquefied oxygen,liquefied nitrogen,liquefied hydrogen.Extended bonnet design of the Pneumatic cryogenic regulating valve to ensure reliability of the stem packing & sealing.Pneumatic cryogenic regulating valve temperature rating: -196°C ~+ 45 °C.

Technical specification

2.1Date sheet

| Pneumatic cryogenic control valve Body type: | straight through casting globe type |

| Valve plug type: | non-balanced single seat plug type |

| Nominal size: | DN20~200,、 NPS 3/4〞~ 8〞 |

| Nominal pressure: | PN16 ~ 100、 CLASS 150LB ~ 600LB |

| Connection: flange: | FF、RF、MF、RTJ |

| Welding: | SW、BW |

| Flange dimension: | According to to IEC 60534 |

| Pneumatic cryogenic regulating valve Bonnet type: | Ⅲ:Low temperature extended type(-196℃~ 45℃) |

| Packing: | V type PFTE packing, flex. graphite packing, etc. |

| Gasket: | Metal graphite packing |

| Pneumatic cryogenic regulating valveActuator: | Pneumatic: multi-spring diaphragm actuator, piston type actuator. |

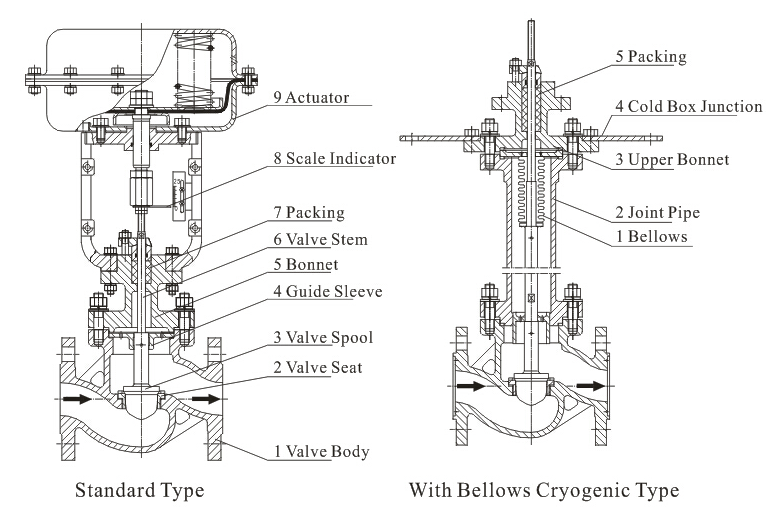

2.2 Cryogenic control valve structure drawing

2.3 Cryogenic control valve material list

| Component name | Control Valve Material |

| Body/Bonnet | LCB/LCC/LF2/CF8/CF8M/CF3M |

| Valve spool/Seat | 304/316/316L(overlaying stellite alloy) |

| Packing | Normal:-196~150℃ is PTFE |

| Gasket | Normal:Stainless steel with flexible graphite,Special:Metal tooth type gasket |

| Diaphragm Cover | Normal:Q235,Special:304 |

| Diaphragm | NBR with reinforced polyester fabric |

| Spring | Normal:60Si2Mn,Special:50CrVa |

| Control valve stem | 2Cr13/17-4PH/304/316/316L |

2.4 Low temperature material suitable temperature list

| Casting | Forging | ||

| Materials | Lowest working temperature |

Materials | Lowest working temperature |

| LCB | -46°C | LF2 | -46°C |

| LCC | -46°C | -46°C | |

| LC1 | -59°C | LF5 | -59°C |

| LC2 | -73°C | LF9 | -73°C |

| LC3 | -101°C | LF3 | -101°C |

| CF8 | -254°C | F304 | -254°C |

| CF8M | -254°C | F316 | -254°C |

| CF3 | -254°C | F304L | -254°C |

| CF3M | -254°C | F316L | -254°C |

2.5 Cryogenic control valve performance

| Pneumatic cryogenic regulating valve Flow characteristic |

Linear, percentage, quick open |

| Allowable range | 50: 1 (CV<6.3 30: 1) |

| Rated Cv value | Percentage CV1.6~630 ,linear CV1.8~690 |

| Pneumatic cryogenic regulating valve Allowable leakage | Metal seal: IV grade(0.01% rated capacity) Soft seal: VI grade(foam grade) Leakage standard: GB/T 4213 |

| Pneumatic cryogenic regulating valve Performance | |

| Intrinsic error % | ±1.5 |

| Return difference, % | ≤1.5 |

| Dead zone, % | ≤0.6 |

| Difference from beginning to end point, % | ±2.5 |

| Rated travel difference, % | ≤2.5 |

2.6 Cryogenic control valve actuator parameter

| Control Valve Type\ Method | Pneumatic diaphragm actuator |

| PZMA-4~PZMA-7 | |

| Multi-spring type | |

| Usage | Regulating type, ON-OFF type |

| Air supply pressure or Power supply voltage | Air supply pressure (Spring range) 140(20~100)Kpa G 240 (40~200) Kpa G 280 (80~240) Kpa G |

| Connector | Air pipe connector: RC1/4 |

| Direct action | Pressure increase, stem descend, valve close. |

| Reaction | Pressure increase, stem ascend, valve open. |

| Input signal | 40~20mA.DC(with positioner) |

| Lag | ≤1%FS(with positioner) |

| Linear type | 2%FS(with positioner) |

| Environmental temperature | -10℃~+70℃ |

| Pneumatic cryogenic regulating valve Accessories |

E/P, P/P valve positioner, filter regulator, valve converter, solenoid valve, limited switch Non-standard accessories, need special customized notes. |

2.7 Cryogenic control valve technical parameter

| Seat diameter(mm) | 10 | 12 | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | |

| Rated Cv | Percentage | 1.6 | 2.5 | 4.0 | 6.3 | 10 | 16 | 25 | 40 | 63 | 100 | 160 | 250 | 400 | 630 |

| Linear | 1.8 | 2.8 | 4.4 | 6.9 | 11 | 17.6 | 27.5 | 44 | 69 | 110 | 176 | 275 | 440 | 690 | |

| Nom. size | Travel | Option flow characteristic Cv. (★standard ●recommanded ○customized) | |||||||||||||

| DN20 | 16mm | ● | ● | ● | ★ | ||||||||||

| DN25 | ● | ● | ● | ● | ★ | ||||||||||

| DN32 | 25 mm | ○ | ○ | ○ | ○ | ○ | ★ | ||||||||

| DN40 | ○ | ○ | ○ | ○ | ● | ★ | |||||||||

| DN50 | ○ | ○ | ○ | ● | ● | ★ | |||||||||

| DN65 | 40mm | ○ | ○ | ○ | ★ | ||||||||||

| DN80 | ○ | ○ | ○ | ● | ★ | ||||||||||

| DN100 | ○ | ○ | ○ | ● | ● | ★ | |||||||||

| DN125 | 60mm | ○ | ○ | ○ | ★ | ||||||||||

| DN150 | ○ | ○ | ● | ★ | |||||||||||

| DN200 | ○ | ○ | ● | ● | ★ | ||||||||||

| Pneumatic actuator Diaphragm area, Ae(cm2) |

PZMA-4 | PZMA-5 | PZMA-6 | PZMA-7 | |||||||||||

| 280 | 400 | 600 | 1000 | ||||||||||||

| Action | Spring range | Pneumatic cryogenic regulating valve Metal sealing allowable pressure difference (MPa) |

|||||||||||||

| Air open | 20-100KPa | 4.46 | 3.09 | 1.98 | 1.16 | 0.7 | 0.44 | 0.28 | 0.18 | 0.17 | 0.11 | 0.07 | 0.07 | 0.05 | 0.03 |

| 40-200 KPa | 6.4 | 6.4 | 5.94 | 3.34 | 2.14 | 1.31 | 0.84 | 0.53 | 0.51 | 0.33 | 0.21 | 0.22 | 0.15 | 0.09 | |

| 80-240 KPa | 6.4 | 6.4 | 6.4 | 6.4 | 4.99 | 3.05 | 1.95 | 1.25 | 1.18 | 0.78 | 0.5 | 0.51 | 0.36 | 0.21 | |

| Air close | 20-100KPa | 6.4 | 6.19 | 3.96 | 2.23 | 2.14 | 0.87 | 0.56 | 0.35 | 0.34 | 0.22 | 0.14 | 0.15 | 0.1 | 0.06 |

| 40-200 KPa | 6.4 | 6.4 | 6.4 | 6.4 | 6.4 | 5.86 | 3.64 | 2.3 | 2.21 | 1.43 | 0.91 | 0.95 | 0.66 | 0.37 | |

| 80-240 KPa | 6.4 | 6.4 | 6.4 | 6.4 | 6.4 | 6.4 | 5.04 | 3.18 | 3.06 | 1.98 | 1.26 | 1.32 | 0.92 | 0.52 | |

FAQ

What are your prices?

Our prices are subject to change depending on supply and other market factors. We will send you an updated price list after your company contact us for further information.

Do you have a minimum order quantity?

Yes, we require all international orders to have an ongoing minimum order quantity. If you are looking to resell but in much smaller quantities, we recommend you check out our website

Can you supply the relevant documentation?

Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required.

What is the average lead time?

For samples, the lead time is about 7 days. For mass production, the lead time is 20-30 days after receiving the deposit payment. The lead times become effective when (1) we have received your deposit, and (2) we have your final approval for your products. If our lead times do not work with your deadline, please go over your requirements with your sale. In all cases we will try to accommodate your needs. In most cases we are able to do so.

What kinds of payment methods do you accept?

You can make the payment to our bank account, Western Union,LianlianPay or PayPal:

30% deposit in advance, 70% balance against the copy of B/L.

What is the product warranty?

We warranty our materials and workmanship. Our commitment is to your satisfaction with our products. In warranty or not, it is the culture of our company to address and resolve all customer issues to everyone’s satisfaction

Do you guarantee safe and secure delivery of products?

Yes, we always use high quality export packaging. We also use specialized hazard packing for dangerous goods and validated cold storage shippers for temperature sensitive items. Specialist packaging and non-standard packing requirements may incur an additional charge.

How about the shipping fees?

The shipping cost depends on the way you choose to get the goods. Express is normally the most quickest but also most expensive way. By seafreight is the best solution for big amounts. Exactly freight rates we can only give you if we know the details of amount, weight and way. Please contact us for further information.

Contact us

For inquiries about product technology, product purchases,catalogs, and quality.